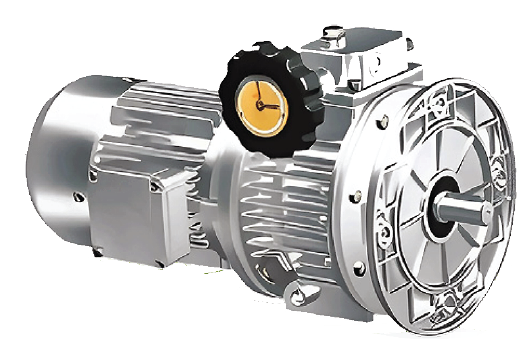

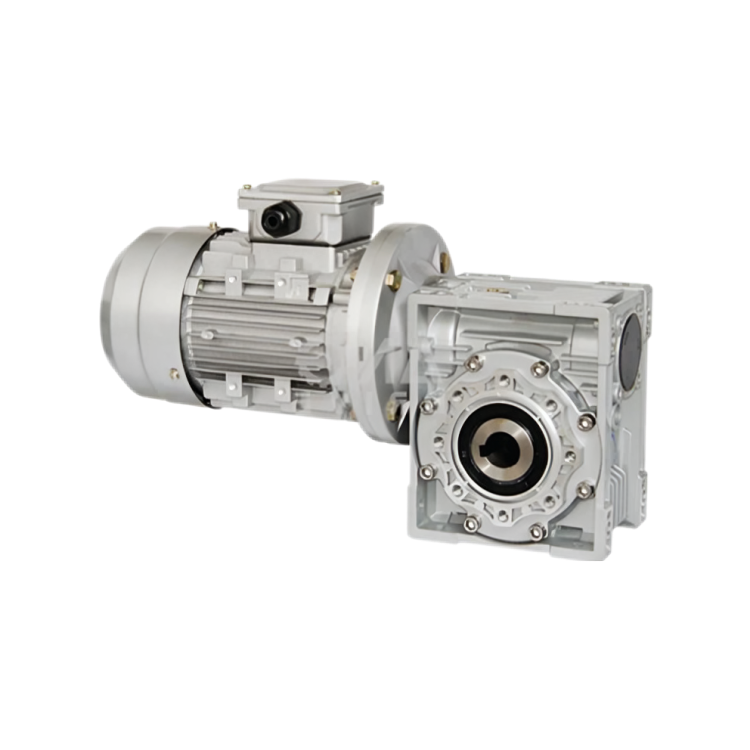

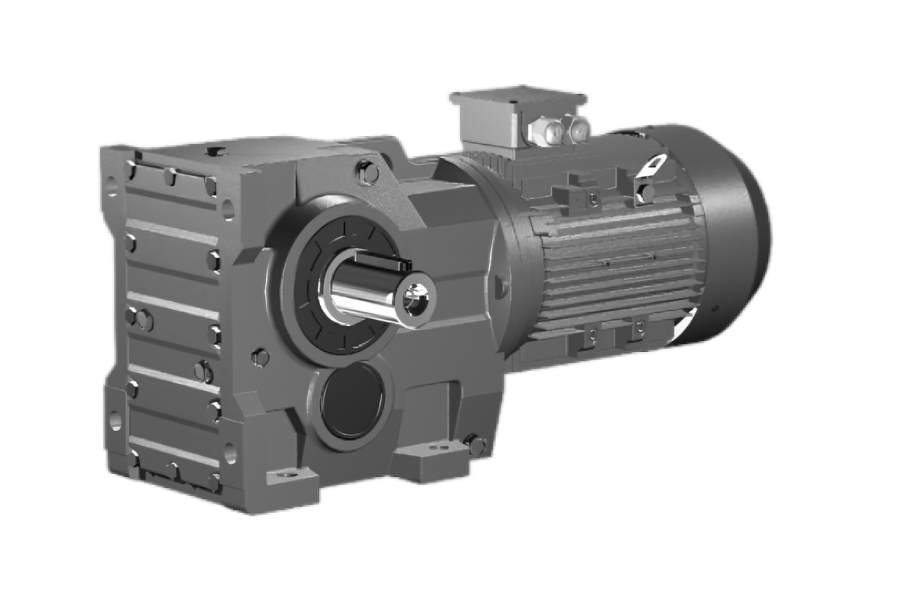

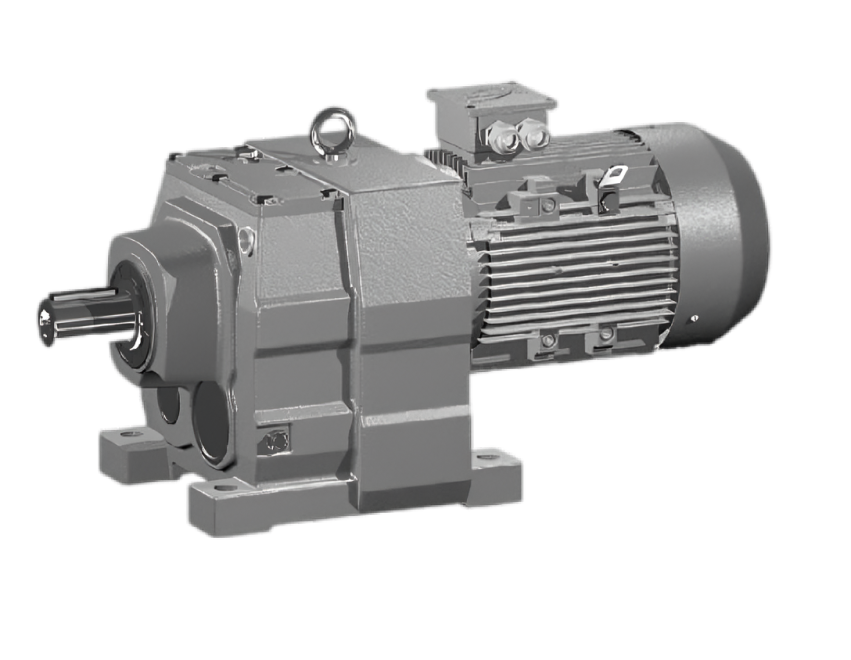

Gear motors represent complete power systems consisting of an electric motor and a gear reduction unit integrated into a single, easy-to-install and configure unit. The gear mechanism is a simple, integrated system that can alter the motor’s speed, direction, and torque. Gear motors are designed to reduce final speed while increasing torque. The primary advantage of using gear motors lies in their block construction design, which simplifies installation and connection with various types of machinery. Our extensive range of high-quality gear motors includes worm gears, straight gears, helical gears, bevel gears, and more, available in capacities starting from 0.18 kW and above.

Our Products and Brands:

Our products include top international brands that comply with European standards, such as

(ROSSI, ALDA, NORD, OME, SEW, and LENZE).

We handle major and widely used gear types, including:

– WS – WSF – WSA – WSAF.

– WK – WKF – WKA – WKAF.

– NMRV.

– WR – WRF.

– MR – MRF.

(The Exclusive Product Catalog)

Applications

These applications include elevators, lifts, medical tables, cranes, robots, and garage door openers, where the goal is to achieve high power at low speeds. Generally, gear motors are used in various integration processes to derive significant power from relatively small inputs.

Why We Are Unique

– Our gear motors are based on a block construction design, making them adaptable to all types of motors and power inputs.

– High transmission efficiency, with a single unit achieving up to 96% efficiency.

– Various installation methods, including horizontal mounting in any position, edge mounting, vertical installation, and more.

– Made from high-quality materials.

– Ensures ease of operation and maximum efficiency through diverse designs suitable for both forward and reverse rotation.