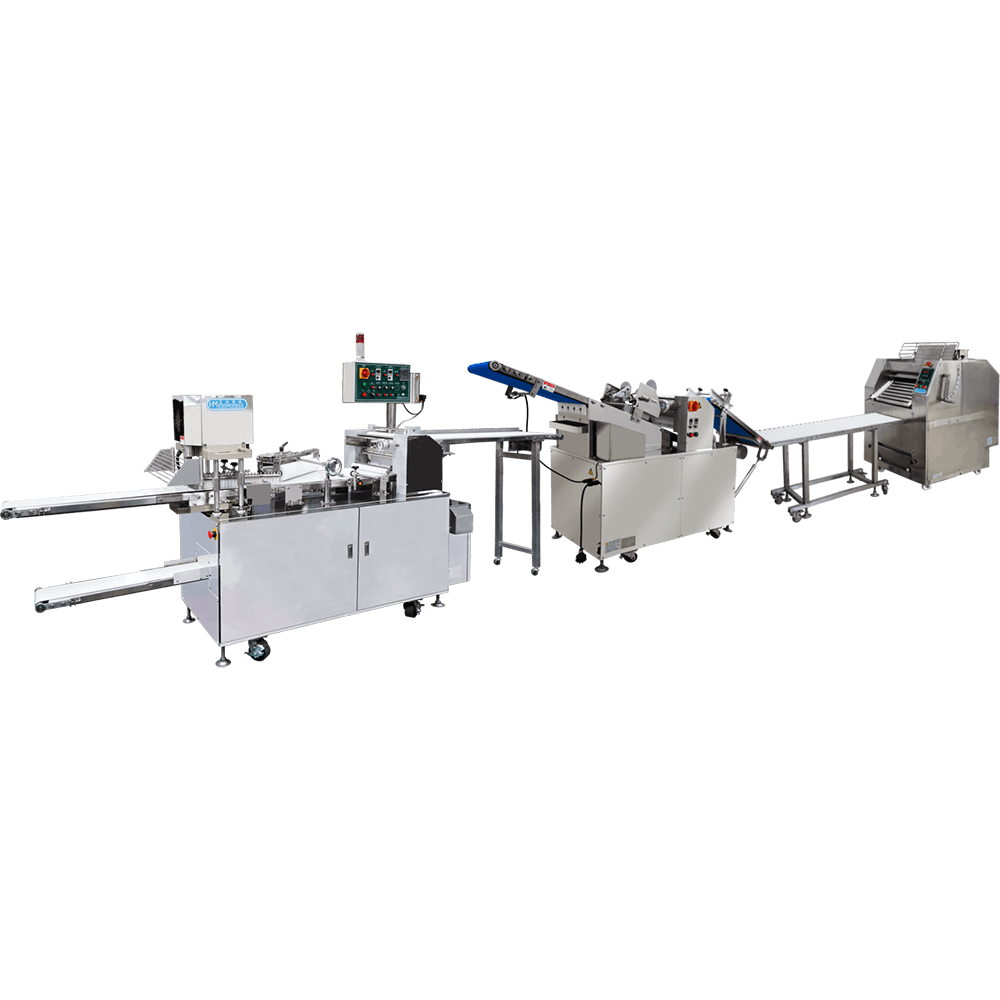

Duck bun production line started with HM-321 dough sheeting machine and HM-322 dough dividing machine. Kneaded dough will be flattened and processed into dough sheet for HM-688 bun – gua bao forming machine. HM-688 will flatten the dough sheet into appropriate thickness, and then apply oil on the dough sheet with a brush set behind the roller. The dough sheet will be folded by a grooved roller and a set of rolling blades. The folded dough sheet will be cut into the shape of a duck bun by the duck bun mold. The forming method can preserve the elasticity and texture, and prevent the folding part from sticking together.